The infrastructure work for the BATEG Lab has been largely completed.

|

The manufacturing infrastructure has been established with a metal 3D printer.

The production of coolant plate designs has been initiated.

|

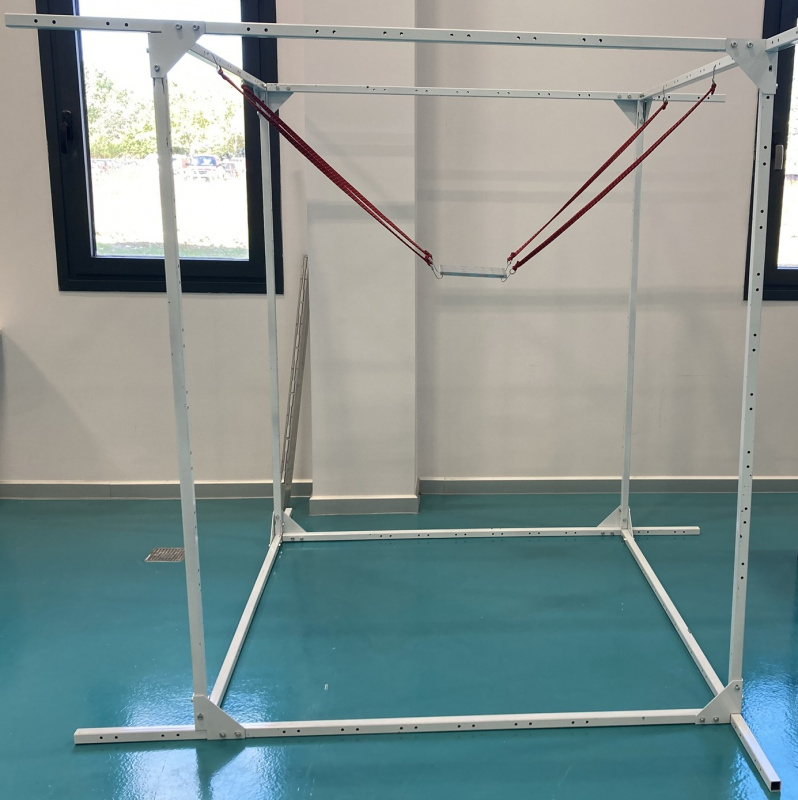

The vibration testing infrastructure for battery carriers and components for electric vehicles has been established.

Vibration Testing Infrastructure

|

The production of parts has started with a metal additive manufacturing device.

Metal 3D Additive Manufacturing Device

|

Thermal and electrical testing infrastructure at the cell and module level for electric vehicles has been established.

WLTP, HPPC, and CC tests have been conducted.

|

Battery module assembly compression fixture

|

Vibration frequency and mode analysis capability has been acquired with the data collection system.

Data Collection and Monitoring System

|

Mechanical testing infrastructure (200kN) has been established (tensile, compression, three-point bending).

Mechanical Testing Infrastructure

|

The production of battery fixture intermediate parts has been initiated.

SLA Printer Group

|